Service Hotline

0411-87307760

Technical selection sales hotline

Technical selection sales hotlineTel:+86 0411 87307760

Mobile:18804209403

Q Q:703738287

E-mail:sales@dlleader.cn

About Nabertherm

Over 60 years of experience in production laboratories and industrial furnaces

The address is located in Bremellithal Town - Made in Germany

500 employees worldwide

150000 customers from over 100 countries

A very wide range of furnace products

One of the largest research and development centers in the furnace industry

Deep Manufacturing

Project planning and construction of customized thermal processing factories for customers, including material handling and loading systems

Innovative control and automation technologies that meet customer needs

Highly reliable and durable furnace system

Customer testing center provides process assurance

The main products we supply include Nabertherm drying oven, Nabertherm air drying oven, Nabertherm circulating air furnace, Nabertherm muffle furnace, Nabertherm tube furnace, Nabertherm box furnace, Nabertherm high-temperature furnace, Nabertherm ash blowing furnace, Nabertherm gradient furnace, Nabertherm melting furnace, Nabertherm fast firing furnace, and various customized special furnace types

Drying oven and circulating air furnace, Tmax: 850 ℃

Oven, Tmax: 300 ℃

Nabertherm has an oven with a safety technology device that meets the EN 1539 standard and can reach a Tmax of 300 ℃.

By reaching a maximum operating temperature of 300 ℃ and forced air circulation, the drying oven can achieve excellent temperature uniformity. They can be used for various applications such as drying, disinfection, and hot storage. The standard furnace type ensures direct supply from the warehouse, Nabertherm, and short delivery time.

TR450 drying oven TR1050 drying oven with double wing furnace door

Tmax 300 ℃

Working temperature range: above room temperature+20 ℃ to 300 ℃

The TR 30-TR420 drying oven is designed as a desktop design

The TR 450-TR1050 drying oven is designed in a vertical position

Horizontal forced air circulation ensures that the temperature uniformity of the empty furnace in DIN17052-1 is better than+/-5 ℃ (when the exhaust valve is closed)

The shell of the kiln is made of stainless steel material 14016 (DIN)

The furnace is made of stainless steel material, 304 alloy (AISI)/(DIN material number 14301), which can prevent rust and facilitate cleaning

Multiple layers of loading can be achieved through grid grids

TR 30-TR240 and TR450 furnace models are equipped with large size, large opening, left open rotary doors with quick release device

TR 420-TR800 and TR1050 furnace models are equipped with double wing rotary doors with quick release devices

The Nabertherm drying cabinets TR800 and TR1050 are equipped with transport casters

The exhaust inside the rear wall can be adjusted steplessly on the front side

PID Microprocessor Controller with Self Diagnosis System

Model TRLS: Safety technology in accordance with EN 1539 standard, used for furnace materials containing solvents, with a Tmax uniformity of+/-8 ℃, according to DIN 17052-1, in an empty furnace (exhaust cover closed)

Controller R7 (or C450 for TRLS)

TR240 drying oven

Overtemperature protection limiter, which adjusts the disconnection temperature according to EN 60519-2 standard thermal protection level 2 to prevent overheating of the kiln and workpiece

Continuously variable speed control of air circulation fan

Material Window

With removable additional grid board and slots

Side air intake device

Electric rotating device (relevant sample racks will be customized according to the loading)

Exhaust pipe DN80

Transport casters for TR 240 TR 450 models

Expansion method of quality requirements, in accordance with AMS2750E or FDA

TR30 drying oven with window TR60 drying oven

Nabertherm box dryer, Tmax 260 ℃

The KTR series box dryer can be used for various drying processes and heat treatments of batches, and the Nabertherm application temperature can reach up to 260 ℃. Due to the powerful power of the air circulation device, Nabertherm can achieve temperature uniformity of the box dryer in an effective space. The wide range of accessory supply ensures that suitable Nabertherm box dryers can be customized according to different process requirements.

KTR6125 DT box dryer KTR6125 box dryer

Tmax 260 ℃

Electric heating (using a heater equipped with a built-in chrome steel heating element) or gas heating (blowing hot air into the intake device for direct or indirect gas heating)

Optimal temperature uniformity according to DIN17052-1, up to+/-3 ℃ (for models without entry marks)

By using high-end mineral wool insulation materials, the outer wall temperature is lower than the ambient temperature plus 25 ℃ · high gas exchange rate, ensuring a rapid drying process

KTR2300 and above furnace models are equipped with double wing doors

Nabertherm comes with a temperature selection limiter that can be manually reset and used for thermal protection level 2 in accordance with EN 60519-2 standard, to protect the drying oven and goods

Including bottom insulation material

Controller B400 (5 programs, each with 4 program segments), replacing the standard controller

Nabertherm provides an entry passage for loading trucks to enter on a flat surface

Using a loading forklift to load the base of the furnace

Additional doors at the rear for loading from both sides or for use as gate furnaces

Blowing system with manual or automatic control exhaust cover for rapid cooling

Program control switch for exhaust valve

Adjustable circulating airflow, recommended for lightweight or sensitive batch processes

Window and furnace chamber lighting devices

Loading truck with or without shelf system

Control and record the process through VCD software package, or monitor using Nabo Thermal Control Center NCC

Entry track with sealed seat The bottom plate can be inserted on the roller

Air circulation box furnace, Tmax 850 ℃

Nabertherm, a traditional air circulation box furnace, has significant characteristics of good temperature uniformity. The Nabertherm furnace type is particularly suitable for annealing, crystallization, preheating, hardening, and other operations, but it can also be used in various tool manufacturing processes. Due to its modular construction, the air circulation furnace can be optimized and adjusted through various accessories to meet specific operational requirements.

Desktop NAT15/65 air circulation box furnace

Tmax 450 ℃, 650 ℃, or 850 ℃

Nabertherm utilizes stainless steel air baffles to achieve optimal temperature distribution through horizontal air circulation

Left opening rotary furnace door

Optimal temperature uniformity according to DIN 17052-1 in the empty furnace workspace, up to+/-4 ℃ (up to+/-5 ℃ for NAT15/65 and NAT30/85)

The scope of supply also includes one layer board and guide rails for the other two plug-in boards (NAT 15/65 and NAT30/85 type non layer boards)

Nabertherm's scope of supply also includes bottom brackets, with NAT 15/65 and NAT30/85 being desktop models

Controller B400/C410 (5 programs, each with 4 program segments)

Optimal temperature uniformity in accordance with DIN 17052-1, up to+/-3 ℃ in the empty furnace workspace

Inlet and exhaust valves for drying

Controllable fan for auxiliary cooling

Manual lifting door (suitable for furnace type NA 120/)

Pneumatic lifting door

Adjustable circulating airflow, recommended for lightweight or sensitive batch processes

Additional plug-in board

Air supply box for different loading methods

Loading system, electric rolling conveyor for simplified loading

Material control includes process records of material thermocouples

Thermocouple conduit laminate

The furnace chamber is equipped with a rolling conveyor device

Muffle furnace, Tmax 1400 ℃

Muffle furnace, Tmax 1200 ℃

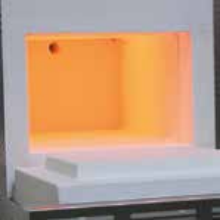

The Nabertherm L1/12-LT40/12 series muffle furnaces are suitable for daily laboratory applications, and Nabertherm has won widespread recognition for many years. The outstanding roasting effect, modern exterior design, and high reliability are the outstanding features of this type of muffle furnace. You can choose to equip the Nabertherm muffle furnace with an open or open door for free.

LT5/12 muffle furnace with lifting door L3/11 muffle furnace with flip door

Standard specifications:

Tmax 1100 ℃ or 1200 ℃

Nabertherm provides optimal temperature uniformity through double-sided heating of ceramic heating plates (L24/11-LT40/12 muffle furnace can be heated on three sides)

When the temperature is above 800 ℃ and the air intake valve is closed, according to DIN17052-1, the temperature uniformity in the working space of the empty furnace is+/-5K

N-type (1100 ℃) or S-type (1200 ℃) thermocouples

Ceramic heating plate embedded with heating wire, easy to maintain and replace

The furnace door can be equipped with an external open door (L) for free (which can be used for workpiece placement), or an upper open door (LT) (with the hot surface facing away from the operator)

There is an adjustable air inlet on the furnace door (see diagram)

The rear wall of the Nabertherm furnace is equipped with an exhaust port

Controller B410 (5 programs, each with 4 program segments) or R7 for L1/12, alternative specification controller

Additional configuration:

Exhaust chimney with exhaust fan or catalytic converter (not applicable for L1 and L15)

Overtemperature protection limiter, which adjusts the disconnection temperature according to EN 60519-2 standard thermal protection level 2 to prevent overheating of the kiln and workpiece

The protective gas interface required for blowing the electric furnace with non flammable protective gas or reaction gas (cannot be combined with exhaust chimney, exhaust chimney with fan, or catalytic converter) is not airtight

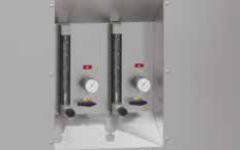

Nabertherm manual or automatic gas distribution system

The thermocouple hole is located on the back wall or on the furnace door

Economical muffle furnace with a Tmax of 1100 ℃

With its remarkable value for money ratio and fast heating characteristics, the Nabertherm compact muffle furnace has been widely used in laboratories. The Nabertherm double-layer stainless steel furnace shell, compact and lightweight structure, and built-in heating elements in quartz tubes ensure the reliable quality of the equipment.

LE9/11 muffle furnace

Standard specifications:

Nabertherm Tmax 1100 ℃

Heating on both sides, with heating elements placed in quartz tubes for protection

Fast heating speed

Heating elements and insulation materials are easy to replace

The shell is coated with industrial grade powder coating

External opening furnace door can be used for workpiece placement

The rear wall of the furnace is equipped with an exhaust port

Compact design and lightweight structure

Installing the controller below the furnace door can save space

Controller R7

Additional configuration:

Nabertherm exhaust chimney with exhaust fan or catalytic converter (not applicable to LE 1)

Muffle furnace with brick insulation layer, Tmax 1300 ℃

The Nabertherm heating element is installed on the support tube and can freely radiate heat in the furnace, so the heating time required for the muffle furnace is extremely short. In addition, the sturdy insulation structure is composed of lightweight refractory bricks, which can achieve a maximum operating temperature of 1300 ℃ for the equipment. If the working temperature needs to be increased, this type of muffle furnace can replace the general L (T)/12 furnace type.

L9/13 muffle furnace equipped with flip door

Standard specifications:

Tmax 1300 ℃

Double sided heating

The heating element installed on the support tube radiates heat freely and has a long service life

The furnace chamber has a sturdy multi-layer lightweight refractory brick insulation structure

The furnace door can be equipped with an external open door (L) for free (which can be used for workpiece placement), or an upper open door (LT) (with the hot surface facing away from the operator)

Adjustable air inlet on the furnace door and exhaust outlet on the rear wall of the furnace

Nabertherm controller B410 (5 programs, each program has 4 program segments), replacing the standard controller

Additional configurations:

Nabertherm exhaust chimney, equipped with exhaust fan or catalytic converter

Nabertherm overtemperature protection limiter, which adjusts the disconnection temperature according to EN60519-2 standard thermal protection level 2 to prevent overheating of the kiln and workpiece

The protective gas interface required for blowing the electric furnace with non flammable protective gas or reaction gas (cannot be combined with exhaust chimney, exhaust chimney with fan, or catalytic converter) is not airtight

Manual or automatic gas distribution system

The thermocouple hole is located on the back wall or on the furnace door

The LT5/13 muffle furnace

The furnace chamber is equipped with advanced lightweight refractory brick insulation structure

Example of over temperature protection limiter

Muffle furnace, Tmax of 1400℃

This series of products have excellent processing technology, advanced and exquisite design, and high reliability. Due to the heating elements being directly installed on the support tube and the heat can freely dissipate into the furnace chamber, these muffle furnaces have particularly short heating times and can be used at temperatures up to 1400℃. Therefore, when short heating times or high application temperatures are required, these muffle furnaces are attractive alternatives to the well-known L(T)/12 type muffle furnace.

Standard specifications:

Tmax of 1400℃ by Nabertherm Heating from both sides Heating elements on the support tube ensure free dissipation of heat and long service life

Adjustable air inlet on the furnace door

Exhaust vent in the rear wall of the furnace Controller B410 (5 programs, 4 program segments per program), as an alternative specification for the controller

Additional configurations:

Nabertherm exhaust chimney, with an exhaust fan or catalytic converter

Nabertherm over-temperature protection limiter, regulating the disconnect

temperature according to thermal protection level 2 of EN 60519-2 standard, to prevent overheating of the kiln and workpieces

Protective gas interface required for blowing protective gas or reactive gas into the electric furnace (cannot be combined with exhaust chimneys, exhaust chimneys with fans or catalytic converters), not airtight

Manual or automatic gas supply system

Muffle furnace with ceramic muffle, built-in heating wire, Tmax of 1100 °C.

When performing heat treatment on corrosive substances, we recommend using the Nabertherm L 9/11/SKM muffle furnace. The furnace is equipped with a ceramic muffle that contains an embedded heating element, providing heating from all four sides. This furnace not only offers excellent temperature uniformity but also protects the heating elements from corrosive air. Additionally, the smooth and almost dust-free muffle ensures exceptional quality.

Standard specifications:

- Tmax: 1100 °C

- Four-sided heating with a ceramic muffle

- Nabertherm ceramic muffle effectively resists corrosive gases and vapors

- Optional outward-opening furnace door (L) for easy sample placement or top-opening furnace door (LT) to keep the operator away from high temperatures

- Adjustable air inlet on the furnace door

- Exhaust port on the rear wall

- Nabertherm controller B410 (5 programs with 4 segments each) as a replacement for standard controllers

Additional configurations:

- Nabertherm exhaust chimney with an exhaust fan or catalytic converter

- Over-temperature protection limiter to prevent overheating of the furnace and samples, adjusted according to thermal protection level 2 of EN60519-2 standard

- Protective gas interface for supplying non-flammable protective gas or reaction gas to flush the furnace (cannot be combined with exhaust chimney, fan-equipped exhaust chimney, or catalytic converter), not airtight

- Nabertherm manual or automatic gas supply system

- Thermocouple holes located on the rear wall or on the furnace door.

L9/11/SKM muffle furnace Four-sided heating of the muffle

Ashing furnace, Tmax of 1100℃

The Nabertherm LV/11 ashing furnace is designed for ashing processes in laboratories with a Tmax of 1050℃. It is commonly used in applications such as determining loss on ignition or ashing food and plastics for subsequent material analysis. The specially designed intake and exhaust systems allow for more than six air exchanges per minute, ensuring that the ashing process always has sufficient oxygen. The incoming air is pre-heated by the furnace heating device to ensure good temperature uniformity.

LV3/11 Ashing furnace LVT5/11 Ashing furnace

Standard Specifications:

Tmax of 1100℃ for Nabertherm furnace.

Double-sided heating.

Embedded heating wires in the ceramic heating plate for easy maintenance and replacement.

More than six air exchanges per minute.

Nabertherm achieves good temperature uniformity through preheating of the intake air. The Tmax uniformity within the specified empty furnace workspace, according to DIN17052-1, is +/-10℃ (starting from 550℃).

Suitable for various standardized ashing processes according to ISO, ASTM, EN, and DIN standards.

Optional door configurations: outward-opening door (LV) for ease of loading/unloading of specimens, or upward-opening door (LVT) to keep the hot surface away from the operator.

Nabertherm B410 controller (5 programs with 4 segments each) as a replacement for standard controllers.

Additional options:

Nabertherm over-temperature protection limiter, regulated according to thermal protection level 2 of EN 60519-2 standard, to prevent furnace and specimen overheating.

Thermocouple bore located on the rear wall or on the furnace door.

Nabertherm loading shelf equipped with sealed or perforated metal plates for loading the furnace at different levels, including a holding rack for inserting/removing the metal plates.

LV5/11Ashing furnace,with thermocouple sleeves in the rear wall of the furnace.

weighing furnace with a combustion loss weighing determination system and software,Tmax1200℃

For Nabertherm L (T) type muffle furnaces, the supply range includes a support system, ceramic connecting rods with furnace internal support plates, precision weighing instruments, and software packages. Four sets of weighing systems with different maximum weighing and scaling ranges are available for selection.

The VCD software package is used for monitoring, recording, and controlling temperature and burnout for process control.

Controller B410 (5 programs, each program with 4 program segments) replaces the specified controller.

Additional configurations

Nabertherm exhaust chimney, equipped with an exhaust fan or catalytic converter. Nabertherm over-temperature protection limiter adjusts the disconnect temperature according to the thermal protection level 2 of the EN60519-2 standard to prevent overheating of the kiln and workpiece.

Thermocouple holes are located on the rear wall or on the furnace door.

Box furnace, Tmax 1400 ℃

Box furnace with brick structure or fiber insulation material,Tmax1400 ℃

For many years, the Nabertherm LH15/12-LF120/14 series large-format box furnaces have been widely recognized and acclaimed as professional box furnaces for various testing operations. These furnaces can be equipped with either robust lightweight refractory brick insulation materials (LH models) or a combination insulation structure (LF models). The LF models utilize low heat storage and fast cooling fiber insulation materials while also incorporating brick insulation materials at the corners of the furnace. You can install numerous additional configurations on this box furnace to meet your processing needs.

LH30/14 Box furnace LH216/12 with a fan can accelerate the cooling time

Standard Specifications:

Nabertherm has furnaces with a maximum temperature of 1200℃, 1300℃, or 1400℃.

The five-sided heating chamber of the Nabertherm furnace ensures good temperature uniformity.

The heating elements, which are mounted on support tubes, radiate heat freely and have a long service life.

The controller is installed on the furnace door and is movable for convenient operation.

The furnace bottom is protected by SiC plates to enhance heating efficiency and facilitate smooth stacking.

The LH furnace model features a multi-layer lightweight refractory brick insulation structure and a special insulation design.

The LF furnace model significantly reduces heating and cooling time with high-quality fiber insulation materials and refractory bricks in the furnace corners. The furnace door adopts a brick-to-brick sealing structure and undergoes manual sanding.

The design of the furnace allows for high power and short heating time.

The self-supporting arched furnace roof provides stability and effectively prevents dust accumulation.

The furnace bottom is equipped with a stepless adjustable air inlet valve and a motor-driven exhaust cover.

The supply range includes supports.

The Nabertherm B400 controller offers 5 programs with 4 program segments each and can replace controllers with similar specifications.

Additional options:

Nabertherm parallel swing doors are used for opening operations in high-temperature conditions, with the back side facing the operator.

The upward-opening furnace door is equipped with a linear motor drive device.

Separate wall-mounted or floor-mounted cabinets are used for installing switch devices.

A cooling system is used to cool the kiln with specified temperature gradients or pre-set fresh air flow rates.

The two operation modes can be switched in segments through the additional functions of the controller.

Nabertherm provides a protective gas interface for supplying non-flammable protective gas or reaction gas for purging electric furnaces.

The gas supply system can be manual or automatic.

Weighing devices are used to determine the combustion loss weight.

Box furnace for annealing, quenching, or brazing,Tmax1280℃

To adapt to the demanding working environment of laboratories, such as heat treatment of metals, Nabertherm furnaces must be equipped with a robust lightweight refractory brick insulation structure. The N7/H-N87/H box-type furnace is the optimal solution for such applications. These electric furnaces can be equipped with various accessories, such as annealing boxes for protective gas processing, roller conveyors, or cooling stations with quenching slots. Therefore, even the most challenging applications like incomplete annealing of titanium in the pharmaceutical field can be easily achieved by Nabertherm furnaces, without the need for other expensive and complex annealing equipment.

Use a material handling cart to operate the protective gas supply box

The deep furnace with three-sided heating is operated using a material handling cart to supply protective gas

Standard Specifications :

Nabertherm maximum temperature 1280℃ The furnace has a deep chamber with three-sided (both sides and bottom) heating function.

The heating elements installed on support pipes radiate heat freely, ensuring a long service life.

The bottom heating is protected by SiC heat-resistant plates.

Complies with DIN17052-1 for optimal temperature uniformity, with a maximum deviation of +/-10℃.

Multi-layer insulation structure reduces energy consumption.

The supply range also includes a bottom support bracket.

N7/H-N17/HR is the desktop model.

Nabertherm parallel guided door opens downward to prevent heat radiation from the furnace door.

Air pressure dampers/springs facilitate door opening and closing.

The B400 controller has 5 programs, each with 4 segments, as a replacement for the specified controller.

High-temperature furnace,Tmax 1800 ℃

Desktop high-temperature furnace with SiC rod heating elements,Tmax 1600℃

Nabertherm's powerful laboratory muffle furnace with SiC rod heating elements is capable of reaching maximum temperatures of 1400°C, 1500°C, 1550°C, or 1600°C. The robust and durable SiC rods, along with short heating times, make this high-temperature furnace widely used in laboratory applications. Depending on the furnace model and operating conditions, the heating time can be shortened to 20-25 minutes at a maximum temperature of 1400°C

LHT01/17D high-temperature furnace,Equipped with a lifting furnace door.

Standard Specifications

Nabertherm's highest temperatures are 1400°C, 1500°C, 1550°C, or 1600°C.

The operating temperature can reach up to 1500°C (specifically for high-temperature furnace LHTC/16), and with higher operating temperatures, the wear rate will definitely increase.

The furnace door can be equipped with an outward-opening door (LHTC) that allows for easy placement of workpieces, or an upward-opening door (LHTCT) that keeps the hot face away from the operator (LHTCT01/16 model high-temperature furnace only comes with a lifting door).

The switch equipment controlling the power of SiC rods is equipped with solid-state relays. The replacement of heating rods is simple.

The intake port of Nabertherm is adjustable, and there is an exhaust port on the top cover.

The C450 controller has 10 programs, each with 20 program segments, and it serves as a replacement for controllers of similar specifications.

Additional options:

Nabertherm over-temperature protection limiter regulates the cut-off temperature according to thermal protection level 2 of the EN 60519-2 standard to prevent overheating of the kiln and workpiece.

Nabertherm provides a protective gas interface for blowing non-flammable protective gas or reaction gas into the electric furnace. The interface is not airtight. It can be operated manually or with an automatic gas distribution system.统

Benchtop high-temperature furnace with MoSi2 heating elements,Tmax 1800℃

The benchtop furnace model of Nabertherm, a compact high-temperature furnace, has various advantages. With superior manufacturing craftsmanship, high-quality materials, and convenient operation, this furnace model has gained widespread use in research and laboratory applications. Even for sintering technical ceramics such as ceramic dental bridges, this type of kiln is the best choice.

Standard Specifications:

Nabertherm offers benchtop furnaces with maximum temperatures of 1600°C, 1750°C, or 1800°C.

The recommended working temperature is 1750°C for the LHT/18 model. However, it should be noted that the wear rate will increase as the working temperature rises.

These furnaces are equipped with high-quality molybdenum disilicide heating elements.

The air inlet is adjustable, and there is an exhaust port on the top cover. The B-type thermocouple is used for temperature measurement.

Nabertherm provides a P470 controller with 50 programs, each consisting of 40 segments.

Additional options:

Nabertherm over-temperature protection limiter, which adjusts the cut-off temperature according to the thermal protection class 2 specified in EN 60519-2 to prevent overheating of the furnace and workpieces.

There is also a protective gas interface for supplying non-flammable protective gas or reaction gas to flush the furnace, with a non-airtight seal.

Both manual and automatic gas distribution systems are available.

High-temperature bottom-lift furnace,Tmax 1700℃

The Nabertherm electric lifting table greatly simplifies the loading of LHT/LB (Speed) high-temperature furnaces. The surrounding heating of the furnace chamber ensures optimal temperature uniformity. For LHT01/17LBSpeed and LHT02/17LB Speed tabletop furnaces, the materials can be placed in furnace crucibles made of industrial ceramics. Up to three crucibles can be stacked, ensuring higher production efficiency.

Standard specifications :

Nabertherm has a maximum temperature of 1650℃, 1700℃ (LHT 16/17 LB).

The high-quality heating elements made of molybdenum disilicide have excellent chemical resistance between the furnace material and heating elements.

The furnace chamber adopts a 3-sided (LHT 02/17 LB Speed) or 4-sided (LHT 01/17 LB Speed) heating design, ensuring excellent temperature uniformity.

The furnace chamber has a volume of 1, 2, or 16 liters, providing a large working area.

The working table is equipped with a high-precision toothed belt electric drive device controlled by buttons.

The furnace top has an exhaust port. S-type thermocouple.

Controller P470 (50 programs with 40 program segments each).

Additional options:

Nabertherm over-temperature protection limiter, adjusting the cut-off temperature according to thermal protection level 2 of EN 60519-2 standard to prevent overheating of the kiln and workpiece.

Stackable crucibles can be used, allowing for two or three layers, depending on the furnace model.

The furnace bottom comes with an adjustable air inlet.

Electrically adjustable furnace bottom LHT01/17LB-LHT01/17LB - Four-sided heating furnace chamber

High-temperature furnace with weighing instrument,Tmax1750℃

These high-temperature furnaces are specially developed by Nabertherm for determining combustion weight loss and thermogravimetric analysis (TGA) in the laboratory. The complete system consists of a high-temperature furnace with either 1600℃ or 1750℃ capability, a working table frame, a precision weighing instrument that passes through the furnace, and powerful software. The software allows for recording temperature changes and weight loss at different time intervals.

LHT03-17D type furnace

Standard Specifications:

Nabertherm maximum temperature of 1600℃ or 1750℃

High-quality molybdenum disilicide heating elements

Double-layered striped stainless steel furnace housing and additional cooling device to ensure low external shell temperature

Adjustable air inlet

Exhaust port on the furnace top

Type B thermocouple

Supply range includes brackets, ceramic connecting rods with internal furnace support plates, precision weighing instruments, and software package

Four sets of weighing systems with different maximum weighing and scaling ranges for selection

Nabertherm provides process control for temperature and burnout through VCD software package for monitoring, recording, and control.

Four sets of weighing systems with maximum weighing and scaling ranges

High-quality molybdenum disilicide heating elements

Floor-standing high-temperature furnace with MoSi2 heating elements,Tmax1800 ℃

Due to its robust and compact vertical design, the Nabertherm high-temperature furnace is suitable for precise operations with high accuracy in laboratory settings. Its excellent temperature uniformity and sophisticated design ensure high quality. Depending on specific applications, you can expand your kiln with various configurations we provide.

High-temperature furnace RHTC80-450

Standard specifications:

Nabertherm maximum temperature of 1600℃, 1750℃ or 1800℃

Recommended operating temperature of 1750℃ (for HT/18 model), increased wear is expected at higher operating temperatures

Double-layer furnace shell structure with fan cooling device to keep the outer wall temperature low

Heating on both sides using molybdenum disilicide heating elements

High-quality fiber insulation material with dedicated backing insulation material

Installation of furnace side wall insulation material composed of grooves and tenon blocks to ensure lower heat loss outward

Long-lasting furnace top insulation material from Nabertherm with special suspension structure

Parallel swing door with chain guiding device for pre-set opening and closing of the door

Two-door structure (front/back) used in high-temperature furnaces starting from HT 276/...

Labyrinth seal device ensures minimal temperature loss within the door range

Bottom reinforcement system to protect the bottom fiber insulation layer, standard from HT16/16 (unit load of 5 kg/dm2)

Exhaust outlet on the furnace top with an electric exhaust valve controlled by additional functions of the controller

Control of the heating elements through thyristors.

Additional configurations :

Nabertherm cooling system is used for cooling the kiln with predetermined temperature gradients or pre-set fresh air volume.

The two operating modes can be switched in segments through the additional functions of the controller.

Safety package for venting gases into the air.

Venting of technical ceramics is a critical process due to the release of hydrocarbons.

Carbon dioxide is flammable and the danger lies in the formation of combustible mixtures in the furnace chamber.

Nabertherm offers customized safety packages based on the process and binder usage to achieve safe kiln operation. Special heating elements from Nabertherm for sintering zirconia.

Protective gas interface for supplying non-flammable protective gas or reaction gas to purge the electric furnace.

Automatic supply system with solenoid valves and rotor flow meters, controlled through additional functions of the controller.

Process box used to improve gas density and protect the furnace chamber from contamination.

Lightweight refractory bricks used for the insulation layer at the bottom of the furnace to withstand high furnace bottom loads (Tmax 1700℃).

Lift-up furnace door. Automatic door lock, including door contact switch. Ethernet interface.

Floor-standing high-temperature furnace with SiC rod heating elements, Tmax 1550 ℃

The box-type high-temperature furnaces, models HTC16/16-HTC450/16, manufactured by Nabertherm are particularly suitable for sintering heat treatment. They utilize vertically suspended SiC rod heating elements and can reach a maximum operating temperature of 1550°C. For certain heat treatment processes, such as sintering zirconium oxide, using SiC rods is more appropriate than using molybdenum disilicide thermocouples, as the former does not react with the furnace material. These furnaces have a similar basic structure and can be equipped with the same additional accessories as the models in the HT manufacturing series.

Standard Specifications:

- Maximum temperature of Nabertherm: 1550°C

- Double-walled furnace shell structure with fan cooling device to keep the exterior wall temperature low

- Heating from both sides using vertically suspended SiC rods

- High-quality insulation material with dedicated backing insulation material from Nabertherm

- Furnace sidewalls insulated with groove and tenon blocks construction to minimize heat loss outwardly

- Long-lasting top insulation material with a special suspension structure

- Parallel swing doors with chain guide device for pre-determined opening and closing without damaging insulation material

- Two-door structure (front/back) used in high-temperature furnaces starting from model HTC276/...

- Maze seal system ensures minimal temperature loss within the door range

- Furnace bottom reinforcement provides a stable loading surface, protecting the bottom fiber insulation material from damage and increasing the loading capacity

- Exhaust outlet at the furnace top with an electric exhaust valve controlled by additional functions on the controller

- Control of heating elements through thyristors

- Nabertherm temperature selection limiter with adjustable cut-off temperature in accordance with the second temperature protection level specified in EN 60519-2 standard for over-temperature protection of the furnace and products.

SiC rods and optional porous intake tube together automatic gas supply system

high-temperature furnace with MoSi2 heating elements and lightweight refractory brick insulation layer, Tmax 1700℃

The most notable feature of the Nabertherm HFL16/16-HFL160/17 high-temperature furnace is its robust lightweight refractory brick lining. This furnace model is particularly suitable for processing operations that involve corrosive gases or acidic substances, such as glass melting.

Similar to the HT-type high-temperature furnace, Nabertherm offers a maximum temperature of 1600℃ or 1700℃. It utilizes lightweight refractory brick insulation material that is durable and comes with dedicated backing material to enhance insulation efficiency.

The furnace bottom is constructed with lightweight refractory bricks to support higher load capacity, ensuring stability and safety during the processing.

Additionally, the furnace is equipped with parallel swing doors guided by chain devices. This design allows for controlled door opening and closing without damaging the insulation materials.

The labyrinth sealing system ensures minimal temperature loss within the door range. This sealing mechanism effectively prevents heat and gas leakage, improves energy efficiency, and maintains a stable high-temperature environment.

In summary, the Nabertherm HFL16/16-HFL160/17 high-temperature furnace stands out with its robust lightweight refractory brick lining, high-temperature capabilities, and reliable insulation design. It is well-suited for various high-temperature heating applications.

Flame-retardant protective inflation system Top cover internal thermocouple sleeve

Refractory insulation layer and molybdenum disilicide heating element

Kiln suitable for special applications

Nabertherm fire assay/ash blowing furnace, Tmax 1300 ℃

Nabertherm gradient furnace or stretching annealing furnace, with a Tmax of 1300 ℃

Nabertherm fast firing furnace, with a Tmax of 1300 ℃

Nabertherm laboratory melting furnace with a Tmax of 1400 ℃

No file

No file