Service Hotline

0411-87307760

Technical selection sales hotline

Technical selection sales hotlineTel:0411-87307760

Mobile:18804209403

Q Q:703738287

E-mail:sales@dlleader.cn

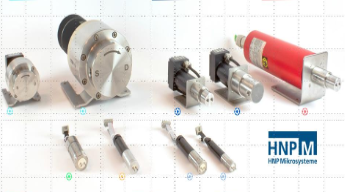

Ⅰ.Introduction to HNP Mikrosysteme Company

HNP Mikrosysteme was established in 1998 and is located in northern Germany. Developing, manufacturing, and selling micro gear micro flow pumps worldwide, which can quickly and accurately transport and fill small amounts of liquid, and quickly and accurately inject small amounts of liquid. On this basis, HNPM company also provides customized services for developing ingredient systems. The application fields include analytical instruments, mechanical engineering, chemical and pharmaceutical processes, as well as new fields such as fuel cells, biotechnology, organic electronics, and aerospace.

The company has approximately 90 employees, including scientists, engineers, and designers, engaged in product development, design, driving and control technology, software development, assembly, quality assurance, management, and more. Micro ring gear pump (mzr ®- Pumps improve the performance of applications such as liquid transfer, infusion, filling, or transportation, and can assist technical personnel in researching and developing new products. Effectively completed tasks in the field of traditional microfluidics and opened up new technological fields. It has won numerous awards in the field of micro technology with its innovative concept.

Ⅱ.The principle of HNPM micropump

The micro ring gear pump is a miniaturized rotary positive displacement pump. Based on the principle of micro ring gears, it has an inner toothed outer rotor and an outer toothed inner rotor. The inner rotor has one tooth less than the outer rotor, with a tooth ratio of 6/7 or 10/11. The manufacturing tolerance of the rotor is within the range of a few micrometers. The shaft of the micro ring gear pump is connected to the internal rotor and powered by a precisely controlled electric motor. The outer rotor can be rotatably installed and driven by the inner rotor. As the rotors rotate around their offset axis, the volume of the pumping chamber increases on the input side and decreases on the output side of the pump. Generate a uniform and low pulsating flow rate between the renal inlet and outlet. Based on the above principles, HNPM micropumps have the characteristics of low pulsation and high accuracy, making them suitable for the transportation of micro flow and high viscosity liquids.

Ⅲ.The product series of HNPM micropumps

The HNPM mini ring gear pump series products include 5 major series of mzrs ®‑Pumps pump, used for dosage and quantification from low viscosity to high viscosity liquids. According to different models, the dosage volume varies from 0.25 μ Starting from l, the flow rate starts from 1 μL/h to 1.1 L/min, pressure from 0 to 150 bar. The range of liquid viscosity is from 0.3 to 1000000 mPas There are also explosion-proof versions, suitable for hazardous explosion-proof environments.

HNPM micro metering pump, HNPM micro pump, HNPM sealed inert pump, HNPM low pressure pump, HNPM module pump, HNPM magnetic seal pump, etc.

The characteristics of HNPM micropumps are low pulsation, low shear stress, low dead volume, long service life, light weight, compact structure, and wear-resistant and corrosion-resistant materials. Especially suitable for challenging liquid transportation tasks, such as high viscosity liquids, corrosive liquids, low-temperature, high-temperature liquids, hazardous and explosive liquids, etc.

1. HNPM High Performance Pump Series - Precision Dose Micropump

The high-performance pump series is very suitable for challenging metering tasks that require high precision, medium pressure range, high temperature, and viscosity range of 0.3-1000000mPas. The pump has a double-sided bearing system driven by a powerful DC servo motor with an integrated controller. There are multiple additional modules to choose from, such as fluid sealing modules, heating modules, insulation modules, or gear modules. High performance micro flow pumps are recommended for mechanical and equipment engineering. Based on the size of the pump, standardized interfaces of 1/4 "-28 UNF, 1/8" NPT or 3/8 "NPT are available.

Model: mzr-2905 micropump, mzr-4605 micropump, mzr-7205 micropump, mzr-11508 micropump

Advantages: High pressure differential, high viscosity, optional heating function, optional gearbox, explosion-proof directive version.

The high-performance pump series can add auxiliary modules to the pump, such as providing fluid sealing modules for dosage air and humidity sensitive liquids or vacuum applications, and adding reducers for high viscosity liquids and liquid transportation under high pressure. Add a thermal insulation module for conveying cold and hot liquids at different temperatures (-20 ℃ to 200 ℃), and add a heating module to heat the pump head to maintain the temperature of the liquid, with a high temperature of up to 150 ℃.

2.HNPM low-pressure pump series

The low-pressure pump series is suitable for precision metering tasks of low pressure and low viscosity, especially for non lubricating liquids with small doses. Using a DC mini motor, the pump has a small size and low power consumption, making it easy to integrate into OEM applications. It is an innovative micropump that can be used for analytical instruments. A liquid with low pulsation, high precision, and low shear stress, which can accurately distribute low doses within a micro lift range. Due to its compact and compact design. This pump is suitable for dosage and measurement of low pressure and low viscosity liquids, such as deionized water, aqueous solutions, methanol, solvents, engine oil, and lubricants. The diameter of the mzr2521 micropump is 13mm, the length is 75mm, and the minimum flow rate is 0.25 μ L. The flow range is 0.15 mL/min -9 mL/min, the pressure difference is 0-3 bar, and the viscosity range is 0.3-100 mPas. Low pulsation, low shear stress, and long service life.

The HNPM low-pressure series micropump has a dynamic flow control function, featuring micro delivery and easy calibration. The product models include mzr2521, mzr-2921, and mzr4622. Low pressure micropumps are very suitable for integrating analytical instruments and automation systems, microfluidic systems, and chip experiments. For example, laboratory pipetting robots can integrate 8 low pressure micropumps for multi-channel liquid transfer and movement. Due to its small volume, high liquid transfer accuracy, wide measurement range, reduced valve usage, low maintenance, and long service life, it is highly competitive in automated liquid transfer systems. For example, in the Slug-flow PCR amplification instrument, using an mzr micropump can achieve extremely low flow control and precise feeding.

3.HNPM Sealing and Chemical Inert Series

he sealed and chemically inert series micropumps are generally suitable for corrosive liquids. The rotor and functional components made of nickel based tungsten carbide, zirconia, alumina, and other ceramics provide the pump with high chemical resistance and excellent wear resistance. The bearing material of this pump is made of hot isobaric silicon carbide (SSiC) and alloy C22 (2.4602) shell components, which can be used for demanding oxidation and reduction liquids, acids, alkalis, and solvents. Product models include mzr6355, mzr7255, and mzr11558

Advantages: Sealed design, chemical resistance, replaceable pump head, high working pressure, optional heating function, compatibility with FDA, explosion-proof directive version of the magnetic seal series micro flow pump is driven by a torsion resistant NdFeB magnetic coupling. The magnetic sealing series of pumps can handle liquids that are crystalline, air sensitive, and easily hygroscopic. The compact size of the pump is achieved through a new product design and coordination with an integrated motion controller. This pump can be used in all fields that require leak free operation, long service life, and low energy consumption. Product models include mzr2965, mzr4665, and mzr7265

4.HNPM Modular Series - Micro Ring Gear Pump

Modular micro ring gear pump is suitable for micro corrosive liquids. When equipped with oxide ceramic bearing components, the combination of different materials for the pump body and rotor is determined by the liquid to be transported. The rotor can be made of zirconia based ceramics or nickel based tungsten carbide. The pump casing for liquid connection can be made of alloy C22316L stainless steel, aluminum, and PEEK ™ Different material composition options. This pump covers various applications from analytical instruments to chemistry. The models include: mzr2542 micropump, mzr2942 micropump, and mzr7245 micropump

The product features of modular micropumps include chemical inert materials, high dose accuracy, low pulsation, low shear force, compact structure, long service life, dynamic intelligent driving and control.

5.HNPM explosion-proof series

High performance series pumps and sealed inert pumps. It can be equipped with explosion-proof motors and can be used in areas with potential explosion risks or UL/CSA certification. The pump is licensed in accordance with the ATEX explosion-proof directive of EU Directive 2014/34/EU.

In addition, HNP Mikrosysteme also provides the development of OEM pumps and a complete set of microfluidic modular feeding systems, such as dosage systems (MoDos) suitable for the fields of fine chemicals and pharmaceuticals. This system includes HNPM micropumps, filters, sensors, valves, and controllers to achieve intermittent or continuous liquid feeding. Miniaturized distribution module μ Dispense can be used in analytical instruments and is a compact dosage system that achieves precise doses from microliters to milliliters. The liquid distribution module LiquDos is a multifunctional feeding system used for analysis and research and development, with a touch screen control module that is easy to operate and used for manual or automatic feeding.

Ⅳ. Applications of HNPM Micropumps

The main application fields of HNPM micropumps are in life sciences, chemistry, pharmaceuticals, and mechanical engineering, and their application scenarios include

Analytical instruments Adhesive dosage Pharmaceutical engineering

• Molecular diagnosis • Filling and dosing technology • Fine chemicals

• Sample preparation • Low volume lubrication • Flow chemistry

• Particle analysis • Silicification technology • Chemical engineering

• Biotechnology • Polyurethane Grouting • Coating Technology

• Flow cytometry • Food technology • Laboratory automation

• Chromatography • Aerospace Technology • Organic Electronics

• Vacuum Dose • Laser Technology, etc

No file

No file