Service Hotline

0411-87307760

Technical selection sales hotline

Technical selection sales hotlineTel:+86 0411 87307760

Mobile:+86 18804209403

Q Q:703738287

E-mail:sales@dlleader.cn

About PreSens

Based on research activities that began in the 1980s, PreSens was founded in 1997 as a derivative of the University of Regensburg in Germany. PreSens has become one of the leading companies in the field of chemical optical sensor technology.

German PreSens provides system

Measurement of oxygen in gases and liquids

Non invasive online pH, carbon dioxide, and oxygen measurement

Oxygen and pH sensors for disposable bioreactors

L Micro oxygen and pH sensors

Biomass monitoring for process control in shaking bottles

Dissolved oxygen measurement for fermentation and bioreactor systems

Online oxygen and pH measurement in disposable products such as perforated plates and plastic bags

A two-dimensional mapping imaging solution for oxygen, pH, and carbon dioxide

The core of PreSens optical measurement technology is fluorescence analysis sensitive materials (fluorescence quenching principle)

Fluorescence response of indicator material excited by light pulses

Depending on the number of analyte molecules, the fluorescence signal undergoes a change and quenching

Signal changes can be measured using corresponding instruments

Characteristics of PreSens sensors:

Non invasive measurement (non-invasive measurement)

No drilling or sampling: avoid oxygen entry and carbon dioxide emissions (accurate measurement)

No oxygen consumption

Non glass product probe, no risk of breakage

Signal measurement is independent of flow velocity

Note: Sensors have the advantages of small size, light weight, good electrical insulation, no electric sparks, safety, anti electromagnetic interference, high sensitivity, and easy to use communication skills to form telemetry networks

1. PreSens oxygen meter

Single channel and multi-channel equipment for precise measurement of oxygen

PreSens has the perfect oxygen meter to meet any application needs. They can be used in conjunction with miniature oxygen sensors, non-invasive sensors, flow cells, or immersion probes equipped with stainless steel shells. Portable or wall mounted systems equipped with display screens have enormous storage capacity and can be used independently of computers for a long time. Our small desktop oxygen meter - which can be used as a single channel or multi-channel device - is controlled by a personal computer through the PreSens Measurement Studio 2 software. This software allows for simultaneous control of multiple instruments. The trace oxygen analyzer provides a measurement range of 1 ppb to 100% oxygen. Due to the principle of fiber optic measurement, such instruments can even be used for measurement work in hazardous areas. Here, you will find the ideal oxygen meter to meet your needs!

Microx 4 (trace) and Fibox 4 (trace)

The handheld Microx 4 (trace) and Fibox 4 (trace) devices are ideal tools for on-site research and can be used for the determination of gaseous or dissolved oxygen. By combining different types of oxygen sensors, such equipment can be used for water quality assessment, respiratory measurement, or tissue measurement. This type of oxygen meter is suitable for any place that requires precise oxygen measurement. Due to its splashproof performance and sturdy casing, this type of oxygen meter can be used in harsh environments. Special energy settings for long-term measurement, with almost unlimited storage capacity or graphical display of your measurement results, allowing for long-term and comfortable use independently of the computer.

OXY-1 ST (trace) OXY-1 SMA (trace)

This series of ultra small oxygen meters are powered by USB and controlled by PreSens Measurement Studio 2 software. It can be used with ST/SMA compatible sensor nodes, immersion probes, flow cells, and micro sensors. This series of devices is suitable for almost any field. This device has temperature, pressure, and salinity compensation functions. The Oxy-1 trace series can detect trace oxygen, with a measurement range of 1 ppb to 100%

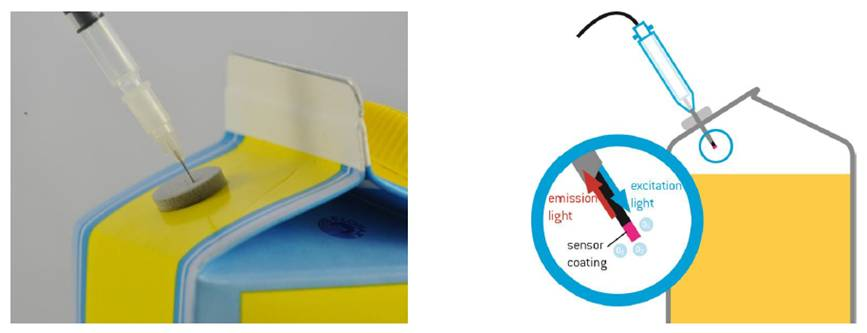

2. PreSens non-invasive oxygen sensor

Non invasive optical oxygen sensors are one of the effective sensors for measuring dissolved oxygen and gaseous oxygen. They can be fixed on the inner surface of transparent glass or plastic materials, and then oxygen concentration can be measured from the outside in a non-contact and non-destructive manner through the container wall. And provide sensor coatings suitable for different concentration ranges.

Characteristics of PreSens Non Immersion Mounted - Oxygen Sensors

1. Online detection

2. Non immersion measurement

3. Dissolved oxygen range 1ppb-45ppm

4. No need to consume oxygen

5. Signal not limited by flow rate

6. Can measure dissolved oxygen and oxygen in air using patch based measurement

PreSens Non Immersion Mounted - Oxygen Sensor Applications:

Bags and disposable bioreactors are revolutionizing the manufacturing of biopharmaceuticals. Our non-invasive oxygen sensor is a tool that allows the culture container to be completely disposable after use. By using non-invasive pH sensors, two key parameters can also be controlled online: oxygen content and pH value.

Shake flask cultivation is widely used in academic and industrial biological process development. Although oxygen supply is one of the main issues in the field of aerobic biological cultivation, there is a lack of sufficient practical monitoring methods for DO, and it is usually assumed that oxygen supply is sufficient. Integrating into transparent bottles, PreSens non-invasive oxygen sensors make online oxygen monitoring possible and provide new insights into metabolic activities.

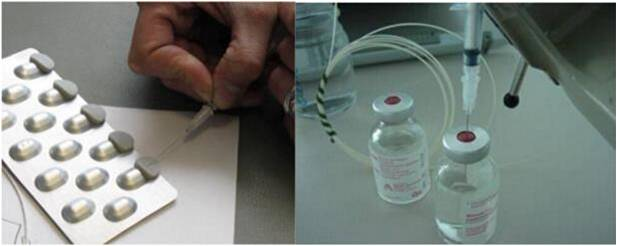

3. PreSens Micro Oxygen Sensor

Micro oxygen sensors are miniaturized chemical optical oxygen sensors designed for all requirements with small end sizes (<50 μ m) Designed for research and packaging applications with fast response time (t90<3sec.). Optical micro oxygen sensor based on 230 μ M quartz fiber optic, capable of providing sensor tip diameters ranging from<50 μ M to 230 μ Between m. Micro oxygen sensors are installed in different shells (needle shell, implantable, micro profile measurement) and provide unique tools for investigating systems that require micro invasive and small sensors.

Application of PreSens Micro Oxygen Sensor

The oxygen inside the packaging can cause certain products to oxidize and deteriorate. Therefore, measuring the oxygen content in packaging or drug bottles is crucial for ensuring filling quality and long-term storage stability. Our micro invasive needle type micro oxygen sensor provides a simple tool for determining residual oxygen in headspace and liquid.

PreSens micro oxygen sensors measure the oxygen content in various volume chambers of tissue engineering structures. For this purpose, sensors as thin as hair are inserted into the structure and then the oxygen content is measured online. Using this method, oxygen partial pressure can be measured with high local resolution and correlated with the quality of structural tissue (composition of extracellular matrix).

PreSens sensors are designed for small headspace, pharmaceutical packaging, and other fields. They can conveniently, accurately, and quickly measure the gas content inside packaging such as drugs and food, providing a more effective solution for headspace residual oxygen and avoiding the drawbacks of electrochemical methods measuring volume and oxygen content limitations.

4. Circulation pool

Chemical optical sensors integrated into plastic or metal flow cells (FTCs) allow non-invasive online monitoring in infusion systems or production lines. The sensor can be fixed on a color coding rod, which can be attached to flow cells of different sizes and shapes, or fixed on an optical exchange window installed inside the flow cell. Polymer optical fibers connect the sensors in the flow cell to the corresponding oxygen meter. Plastic FTC is made of polycarbonate, while metal flow cells can be cleaned in situ or steam sterilized.

Application of Circulation Pools

The pH value and oxygen partial pressure of the bioreactor are controlled by the oxygen flow tank in the bypass, and the flow tank equipped with oxygen and pH sensors can also be installed in the bypass of the bioreactor. After connecting to oxygen and pH meter instruments, their signals can be used to regulate the oxygen content and pH value in the bioreactor.

5. Oxygen probes in research and industrial fields

PreSens optical oxygen probes can provide various designs to meet the needs of most different application fields, such as industrial process control or environmental research. This type of equipment measures gaseous oxygen and dissolved oxygen, and can be used in different measurement ranges from 0.5 ppmv to 100% oxygen. This type of probe uses an advanced stainless steel casing, which is resistant to harsh conditions and can be safely applied in fields such as food production and filling or biotechnology processes. After connecting fiber optic probes to our various oxygen meters, they can even be installed in hazardous areas. The integrated OXYPro series is directly connected to the control unit, making it an ideal solution for process monitoring. The probe can be high-temperature and high-pressure sterilized, in situ sterilized (SIP, 130 ° C1.5 atm), and in situ cleaned (CIP, 80 ° C, 2% sodium hydroxide).

PreSens oxygen probe application

The oxygen probe used by PreSens for online measurement is designed specifically for harsh conditions such as high pressure or oil/water mixtures. This type of system provides high precision, does not contain membranes and electrolytes, and is almost maintenance free. This type of sensor is resistant to high temperature and pressure, steam sterilization, and in situ cleaning.

Low concentrations of oxygen can also affect shelf life and the taste of certain beverages. The PreSens trace oxygen sensor has extremely low detection limits and excellent accuracy, ensuring the quality of oxygen sensitive products such as beer, wine, and soft drinks. Compared to standard electrodes, optical sensors have ultra fast response time and are extremely easy to maintain.

The PreSens series of compact probes integrate the electro-optic module with the sensor in a stainless steel casing. This series of sensors is integrated into a detachable cap and can be easily replaced if necessary. The Oxy base series probes are extremely sturdy and ideal for fields such as oxygen monitoring in fish farms.

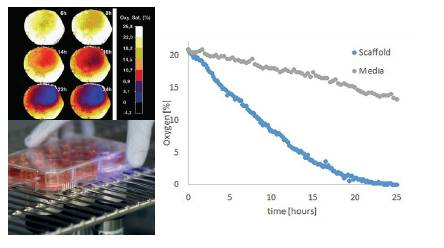

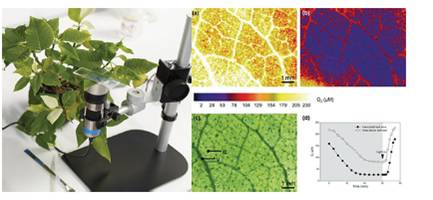

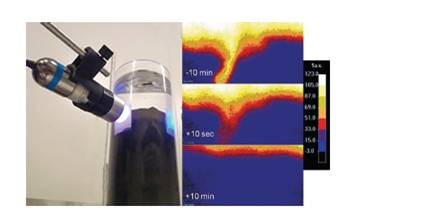

6. VisiSens ™ Imaging system

Record the spatial and temporal distribution of oxygen

Fluorescent chemical optical sensing film combined with VisiSens ™ Imaging technology can perform non-invasive oxygen distribution mapping within heterogeneous samples. The fluorescent sensing film is directly attached to the surface of the sample or placed in a transparent container made of glass or plastic material. The sensing film is available in various sizes and can be cut as needed to convert oxygen content into optical signals. Utilizing VisiSens ™ Imaging equipment that records the spatial and temporal responses of two-dimensional sensors in a non-contact manner.

2D reading

Non contact direct sensing or sensing through transparent walls;

Visually display changes in spatial and temporal gradients;

An image contains multiple measurement points;

VisiSens ™ Application of oxygen imaging system

Cell culture and oxygen content in engineered tissues

The key to cellular metabolism depends on the level of local oxygen supply. Especially in two-dimensional and three-dimensional cell cultures or engineered tissues, cells located in diffusion restricted areas (such as scaffolds or spheroids) may be at low oxygen levels and undergo pH changes. Non invasive continuous two-dimensional mapping can be performed directly in the incubator under growth conditions, and can visually display the two-dimensional distribution of analytes in living samples.

Visualization of oxygen respiration in leaves

Plants are both producers and consumers of oxygen. Visualizing the oxygen content on the surface of plant leaves can reflect the oxygen changes in bright/dark environments. The sensing film is attached to the surface of the leaves, isolating the oxygen in the ambient air from it, and displaying the corresponding analyte at a high resolution level. Using VisiSens ™ It is even possible to study different petal and vascular structures and compare their oxygen consumption.

Oxygen mapping in sediment

Oxygen is a key element in the activity of microorganisms in sediments, as well as various geochemical and life processes. There are significant local differences in oxygen supply, such as at interfaces, different depths, or seabed disturbances. The system can visually display the spatial and temporal dynamics of oxygen over a long period of time. Multiple areas can be compared in one measurement. VisiSens ™ Can perform non-invasive two-dimensional mapping on profiles or sample surfaces

Application

PreSens provides a wide range of sensor systems for end-users in biological process control, biological and environmental research, food and beverage industries, and other industry applications

l Biotechnology and Pharmaceutical Industry

Our biotechnology and pharmaceutical business helps pharmaceutical companies such as Roche and DSM utilize PreSens sensors to enhance their bioprocess development activities. Based on twenty years of customer feedback, our product development department provides efficient solutions to your needs.

l The food and beverage industry

In the late 1990s, we entered the food and beverage business by collaborating with Krones AG, the market leader in beverage filling systems headquartered in Neutraubling. PreSens supplies sensors for checking the oxygen sealing of packaging and special systems for measuring the oxygen permeability of PET bottles from companies such as Nestle, Heineken, or Danisco.

l Biological and Environmental Industry

Our number of clients in the field of biology and environmental research has increased to hundreds, from the University of Alaska in Anchorage to the University of Wellington in New Zealand, with our users located around the world. For over twenty years, we have provided specialized sensor systems for various applications such as respiratory measurement or environmental monitoring.

l Life Sciences and Medical Research Industry

Our latest business area stems from our cooperation with well-known medical technology manufacturers in the medical device industry. PreSens supplies OEM components integrated into more complex medical systems. Micro sensors, sensor nodes, and imaging systems are applied in tissue engineering, microfluidics, and many other medical research fields.

l Industrial and technological industries

Highly robust probes with excellent long-term stability or sensors for non-contact measurement are widely used in technical or industrial applications. Specially designed pipeline integrated flow connectors are used to monitor liquid or gas oxygen content. OEM sensor components can be integrated into customer systems through design.

No file

No file