Service Hotline

0411-87307760

Technical selection sales hotline

Technical selection sales hotlineTel:+86 0411 87307760

Mobile:18804209403

Q Q:703738287

E-mail:sales@dlleader.cn

Ⅰ About Elveflow Company in France

Elveflow in France has been committed to manufacturing high-quality microfluidic processing instruments since 2012, and to date, we have provided up to 2000 systems for scientific research and industrial users. Our product is built around the best-selling OB1 flow controller, including a complete set of components for liquid handling. Our instruments can be controlled using both our software and software development packages, achieving complete automation of your system. Our instruments have modular and scalable features, providing standard and OEM versions. The products include single channel pressure pumps for microfluidic applications, multi-channel pressure vacuum controllers, rotary distribution valves, flow switches, valve and valve controllers, flow sensors, pressure sensors, sensor readers, bubble detectors, liquid storage pipes, and a complete application system for microfluidics.

Ⅱ Elveflow products

1. Multi-channel pressure vacuum controller & single channel pressure pump

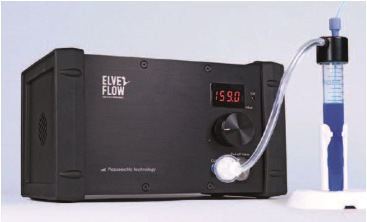

OB1 MK3+is a high-performance microfluidic pressure and flow controller. As a best-selling product of Elveflow, the speed of microfluidics is controlled through pressure and vacuum regulation. OB1 allows for individual control of up to 4 channels of output pressure, from -900 mbar to 8 bar, for various advanced microfluidic applications. Due to the use of advanced piezoelectric technology, OB1 has a stability 10 times higher and a speed 10 times faster than other microfluidic flow controllers. It is a multi-channel pressure and vacuum controller with fast response speed and accuracy in the market, which is standard for pressure and vacuum pumps. It has 4 channels, each with 5 optional pressure ranges, and has the characteristic of modularization and upgradability with software. More channels and application scenarios can be customized according to the actual needs of customers. The multifunctional and powerful OB1 MK3+pressure control system can provide matching flow and pressure control for various experiments. Whether you need pressure or vacuum, low or high flow rates, short-term or long-term experiments, OB1 MK3+is the ideal choice for conducting microfluidic research.

The application fields of OB1 MK3+multi-channel pressure vacuum controller include: digital microfluidics, flow chemistry&polymer synthesis, cell culture, cell perfusion, sequential injection, droplet sequencing, organ chip, increased oil recovery, and chip laboratory.

2.Multi-channel valve

(1) MUX distrib 12-way bidirectional selector valve

MUX distributor is a rotary valve designed for fast liquid switching, a bidirectional 13-port 12-way rotary valve that serves as a selector to sequentially inject a liquid sample into 12 different pipelines or 12 liquid samples into a single pipeline without cross contamination. The micro fluid bidirectional rotary selector valve can be used to process multiple samples and automate experiments. Applications include cell culture on chips, cell response caused by medium changes, drug screening, toxicity testing, sensor testing and calibration, solvent switching in mobile chemistry, and more.

(2) MUX RECIRCULATION 6-port/2-position circulation valve

The MUX recirculation one-way injection circulation valve is a 6-port/2-position microfluidic valve that allows switching between two positions. It can be used for stable unidirectional fluid circulation and sample injection. Accurate liquid injection and long cycle operation can be achieved. The MUX recirculation microfluidic circulation valve is used for accurate sample injection and fluid recirculation. When used in conjunction with the OB1 MK3+pressure flow controller, the MUX recirculation valve (6-port/2 position) allows for fluid circulation in a closed loop, injecting a small amount of sample into the buffer. Applications include cell culture on chips, drug screening, toxicity testing, stem cell detection, organ chips, SPR or TIR imaging combined with microfluidics, heat dissipation experiments, and more.

(3) MUX microfluidic flow switch array

The MUX SERIES flow switch is used for automatic control of microfluidic flow, and can control 16 valves separately, occupying small space.

It is divided into MUX CROSS CHIP, MUX FLOW SWITCH, and MUX QUICH WALVE, and its applications include instantaneous flow stoppage, small sample injection, and sample premixing, starting and stopping of drugs, reagents, and cell culture media in cell biology and fluid chemistry, PDMS microvalves and micropumps, and cell capture device control.

(4) MUX wire microfluidic valve and valve controller

Mux wire is a valve used in microfluidic devices, and the valve controller can simultaneously control 1 to 8 valves, making it easy to integrate. There are low-pressure and high-pressure valves with 2 or 3 channels, and multi flow valves can also be customized according to customer needs, such as 4-in and 1-out valves.

The valve controller can be used to easily control microfluidic valves for fast liquid switching, liquid sampling, stopping, and continuing flow

And complex sequential injection, including flushing, wetting, and sequential injection of several liquids.

3. Microfluidic flow and pressure sensors

(1) Micro fluid flow sensor

MFS thermal flow sensor is a high-precision liquid flow sensor used for low flow monitoring. The thermal flow sensor is equipped with an M8 4-pin electrical interface and can be directly controlled through Elveflow software. The MFS flow sensor has a wide flow range reading, with a flow range of 0.07 to 5000 µ L/min, a corresponding time of 40ms, a resolution of 1.5pL/s, and high chemical compatibility. The flow sensor is used in conjunction with a sensor reader or flow controller to achieve direct flow rate control and bidirectional (forward and reverse) flow rate measurement.

BFS Coriolis flow sensor is a Coriolis flow sensor suitable for microfluidics, with a flow range from 1.6 μ L/min to 500 mL/min, response time: 35 ms, mass flow accuracy: 2% of the measured value (or as required to 0.2%). BFS is characterized by accuracy and a wide flow range, ranging from microliters to milliliters. It is compatible with liquids and gases and is directly applicable without calibration. It can be combined with AF1 series microfluidic pressure pumps, OB1MK3+vacuum pressure controllers, and sensor readers to achieve flow monitoring and control. Application areas include composite semiconductor processing, solar cells and FDP technology, food and pharmaceutical industries, medical trace chemistry or analytical devices, calibration laboratories, etc.

(2) Micro fluid pressure sensor

MPS small volume pressure sensors are suitable for liquids and gases, and are compatible with 3/32 "inner diameter pipelines or 10-32 connectors that are suitable for 1/16" outer diameter pipelines. Monitor low flow rate pressure in microfluidic devices. Suitable for any position in a microfluidic device for measuring and controlling pressure, it is a gauge pressure sensor that measures pressure relative to atmospheric pressure. Accuracy of 0.2% FS, 5 range ranges from 70 mbar to 7000 mbar, internal volume of 7 μL. The stabilization time is 20 ms.

MFP Ruhr interface pressure sensors are suitable for gases or liquids and use standard Ruhr interfaces. This sensor is used to measure the pressure of the fluid medium flowing through the sensor. It has high chemical compatibility, a pressure range of 0-16 bar, MAX pressure resistance of 25 bar, no dead volume, and a flow rate of up to 100 mL/min. Wide media compatibility (contact material: FFKM), FDA certified, suitable for the food industry. We can connect our pressure sensor to the desired position of the microfluidic device, record the pressure through a computer, and use our pressure pump to adjust the pressure or flow accordingly.

Ⅲ ESI - ELVEFLOW Intelligent Software Interface

The Elveflow Smart Interface (ESI) intelligent software interface is suitable for the control software of all instruments, and we can intuitively control our microfluidic instruments with just a few clicks. Due to the use of a scheduler, it is designed for basic control and complex tasks. ESI microfluidic software simplifies many applications, such as continuous fluid generation, volume measurement, dynamic flow monitoring, optical microfluidic control, and more.

Ⅳ Elveflow application system

The Elveflow application package is an all-in-one solution that includes all the equipment required to successfully run microfluidic experiments. Multiple configurations can ensure that you obtain a microfluidic system that fully meets your needs.

The application package of microfluidic droplet generation is an out of the box flow control and chip system for droplet generation, including a complete set of components required for the preparation of droplets and lotion. This application package can achieve rapid synthesis of liposome nanoparticles, continuously producing liposomes and liposome nanoparticles at a speed of 30ml/min. Especially suitable for long-term experiments, it can generate highly monodisperse nanoparticles with a diameter of 30 to 250 nm. You can also directly expand production, producing liposomes and liposome nanoparticle solutions from a few milliliters to one liter! It can be used for the synthesis of liposome nanoparticles (LNP), solid lipid nanoparticles (SLN), and nanoliposomes.

The sodium alginate microsphere preparation application package is used for the preparation of monodisperse hydrogel microsphere, including one pump to transport sodium alginate aqueous solution, and the other pump to continuously transport the oil phase to generate chips through liquid drops, so as to generate sodium alginate liquid drops in the oil. The droplet size is determined by the chip channel size and two-phase flow ratio, which can easily generate micron sized microspheres with repeatability and high monodispersity. Monodisperse hydrogel beads (PDI<5%) are produced. This application package is not only used for the preparation of sodium alginate gel microspheres, but also suitable for a variety of applications, such as drug delivery, wound treatment, cell and tissue culture, etc.

The Cell Biology Application Package is a liquid processing tool used for cell experiments, which can achieve perfusion of multiple culture media. It can perform stable medium perfusion and replacement between several solutions, control shear stress within a large flow range, and automate the microfluidic process of cell culture. It is particularly suitable for cell experiments that change different cell culture media. This cell culture perfusion system is used for cell culture in chip laboratories, mobile cells, and perfusion chambers to create continuous flow and detect flow during the cell culture process.

The Organ Chip Application Package is a fully microfluidic system for organ chip experiments, used for microfluidic flow control and chip solutions for organ experiments on the chip. It can conduct experiments for several days under fully automated conditions. It can effectively simulate the physiological conditions of organs, stably and without pulses, control the flow rate and direction of the medium, and fully control fluid parameters in one or more parallel chips, providing researchers with the ability to reproduce various characteristics of cells and tissues in the internal environment. It can be used for organ research such as lungs, kidneys, and intestines on the chip.

The microfluidic loop application package is used for automated reuse and unidirectional circulation of liquids in microfluidic experiments. It can achieve stable flow without pulses, repeatable, and accurate flow control. It can achieve complete automation for up to a week of experiments at a limited medium volume. The liquid sequence application package is used for rapid conversion of up to 10 fluids under controlled flow rates, for systems that require rapid exchange between multiple solutions while maintaining accurate flow rates. Especially suitable for complex organic chemical reactions, organic synthesis, biosensors, biochemical or electrochemical sensors, test benches, flow chemistry, Seq Fish experiments, analytical chemistry devices, drug and toxicity testing, microsphere synthesis, organic catalysis experiments, and instruments for antibiotic resistance testing.

No file

No file