Service Hotline

0411-87307760

Technical selection sales hotline

Technical selection sales hotlineTel:041187307760

Mobile:19969393953

Q Q:3005205655

E-mail:wjsun@dlleader.cn

FISCHER differential pressure products

FISCHER Mess-und Regeltechnik GmbH is a family-owned enterprise headquartered in Batsalz Uphren, Germany. Its main products include pressure, differential pressure, flow, temperature, liquid level, and other measuring instruments. Its main product is differential pressure measuring instruments, which are high-precision, durable, explosion-proof, and can be customized according to customer needs.

1. Pressure measuring products

Product classification: Pressure gauge, electric contact pressure gauge, pressure transmitter

Display method: pointer, digital display

Measurement range: -1~+600bar

Accuracy: ± 0.25% FS

Models: MA11, MA12, MA13, ME01, ME02, ME05, ME11, ME1, ME13, ME4, ME50, ME69, etc

2. Differential pressure measuring products

Product classification: Differential pressure gauge, differential pressure switch, differential pressure transmitter, differential pressure gauge

Display method: pointer, digital display

Measurement range: -1~+40bar (minimum range 25Pa)

Accuracy: ± 0.1% FS

Models: FISCHERDA01, FISCHERDA02, FISCHERDA03, FISCHERDA08, FISCHERDE03, FISCHERDE05, FISCHERDE13,

FISCHERDE15, FISCHERDE27, FISCHERDE43, FISCHERDE44, FISCHERDE45, FISCHERDE46,

FISCHERDE49, FISCHERDS11, FISCHERDS13, FISCHERDS21, FISCHERDS27, FISCHERDS31, etc

![1698040445500546.png ]MFDU_I`ZXJPHM549APXW63.png](https://en.dlleader.cn/uploadfile/ueditor/image/20231023/1698040445500546.png)

3. Working temperature measuring products:

Product classification: thermal resistance, thermocouple, temperature transmitter

Display method: pointer

Measurement range: -50~+600 ℃

Accuracy: ± 0.08% FS

Models: TS01, TS61, TW10, TW23, TW30, TW40, TW50, TW68, TW70, etc

Application :

Suitable for all industrial fields, especially FISCHER differential pressure measuring instruments, widely used in automotive coatings, pumps, fans, filtration systems, indoor environmental control, etc., such as clean rooms/cleanrooms.

Certification:

"97/23/EC quality system", "2011/65/EU-RoHS certification", "ISO9001: 2008 quality system certification", "ATEX94/9/EC explosion-proof equipment directive"

OEM equipment

FISCHER proprietary technology - customer customized solutions

In addition to standard equipment, we also develop and manufacture solutions related to measurement and control technology in the form of OEM. OEM products are mainly manufactured for direct integration into complete solutions.

On the one hand, OEM products fully comply with the customer's system architecture, and on the other hand, they are economically attractive. Therefore, FISCHER places special emphasis on continuous communication with customers during the OEM equipment development phase. The manufacturing steps have been coordinated with the customer:

Preparation, development, prototype, and certification of contracts and engineering specifications

Cleanroom technology

Cleanrooms can be found in many industrial fields and clinical environments, such as the pharmaceutical industry, semiconductor and solar industries, aerospace engineering, nanotechnology, medical engineering, research, pharmacies, etc. Cleanrooms are installed in places where products need to be protected from air particle pollution.

In order to separate the clean room from the surrounding rooms and prevent the infiltration of particulate matter, appropriate ventilation systems need to be installed according to the classification of the clean room to create a pressure difference. It is also possible to measure and record room temperature and/or indoor air humidity as control variables for building control systems.

The FISCHER measuring instrument provides the highest level of accuracy and long-term repeatability of measurement values.

FISCHER Pressure Transmitter Product

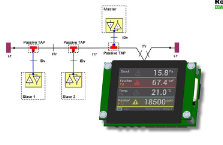

1. FISCHER PRO LINE ® DE90- New Product

The multifunctional differential pressure transmitter DE90 can be used to measure the pressure and differential pressure of medium air and neutral gas.

2. FISCHER in Touch EA15

Our universal measurement indicator EA15 and data logger can monitor, record, and optimize your processes. Using dynamic filters for monitoring can reduce operational costs.

3. Digital 2-channel differential pressure transmitter DE43 for explosive hazardous applications

Capable of connecting to MODBUS compatible automation systems, 2-channel transmitter DE43 is now available for EX Zone 2 and Zone 22. This device is typically used for technical air conditioning, ventilation, and surface applications.

4.DA09 Welding Execution

Differential pressure measurement devices are applied in the fields of chemistry, petrochemistry, process engineering, and marine and offshore technology. Due to the welded structure, no elastomer seal is required. The diaphragm pressure gauge has been completely revised and replaced with a threaded structure

The accuracy level has been greatly improved from 2.5% to 1.6%.

5.DE23 and DE46

Differential pressure transmitter, measurement range for special low-pressure applications (Pa)

For room pressure monitoring (such as in clean rooms), FISCHER also provides differential pressure transmitters DE23 and DE46, with a measurement range of -20...+80 Pa.

In the past, the measurement range was unidirectional, designed for overpressure, negative pressure, or larger measurement ranges, with low resolution (such as 0...+100pa-100...+100pa, respectively).

The bidirectional measurement range can detect flow backflow. The overpressure measurement range can be applied to clean rooms of various pressure levels, and a relatively small basic pressure range can provide high measurement accuracy.

The sensors of models DE23 and DE46 both have long-term stability and good reproducibility of measurement results.

6.Provide certificates - DS21 and NK10

FISCHER equipment is also used for safety related applications. You can find the available certificates on our homepage. Our measuring instruments can be used as flow and liquid level protection devices, as well as flow controllers and limiters.

The DS21 differential pressure measurement and switching device is used as a flow protection device in the thermal oil system in accordance with DIN4754-2:2015-03 and the hot water system in accordance with the VdTÜ meter "flow rate 100".

Another example of DS21 is its application as a flow limiter in water tube boilers and system components (steam boiler plants) according to DIN EN 12952-11:2007-09 and DIN EN 12953-9:2007-09.

Based on DIN4754-3:2015-3, the NK10 liquid level controller will be used as a liquid level protection device for the thermal oil system

7. FISCHER differential pressure transmitter DE45

DE45 can measure positive pressure, negative pressure, and pressure difference, and is widely used in space environmental control, ventilation and air filtration treatment, spray room air quality control, furnace negative pressure and smoke exhaust control, etc.

FISCHER differential pressure transmitter has the following characteristics: sturdy and durable, overpressure protection, maintenance free, optional output signal, and the ability to set instrument parameters through a computer.

DE45 is a multifunctional pressure measuring instrument with analog signal output and two switch contact outputs. This instrument uses a piezoresistive sensor to convert the differential pressure change signal into a voltage change signal. The CPU (uC) obtains the pressure difference through an A/D converter and compares it with the set value, sends an alarm signal, measures the value on an LED display, and outputs the analog quantity of the measurement signal to the controller through a D/A converter.

8.Digital differential pressure transmitter DE39

The pressure is measured by two integrated ceramic sensor elements, and the measurement signals P+and P - are analyzed by digital measurement sensors.

Allow for setting two independent switching points and two programmable output signals. The measurement results can be displayed together or separately, alternately. Set the output for the nominal pressure and differential pressure measurement range of the integrated sensor, and indicate it on the nameplate.

The device has two operating modes:

(a) Differential pressure measurement

Output signals and pressure difference( Δ P) Proportional. The two output signals are proportional to the pressure and can be assigned to the signal P+or P - independently.

(b) Dual channel relative pressure measurement

The output signal is proportional to pressure, where output (Sig1) is allocated to pressure (P+) and output (Sig2) is allocated to pressure (P -).

The pressure pipeline needs to be installed in an inclined position, so that there will be no air pockets when measuring fluid and no water pockets when measuring gas. If the required inclination is not achieved, water or air filters need to be installed in appropriate locations.

If water is used as the measuring medium, the device needs to be frosted.

The pressure pipeline should be as short as possible, and there should be no bends during installation to avoid delays.

The pulsating pressure on the system side can cause wear and functional issues. To ensure this, we recommend installing absorption elements on the pressure pipeline.

If the pressure sensing pipeline has already been pressurized during debugging, zero point control and adjustment cannot be carried out. In this case, the device should only be connected to the main line without a pressure sensing line.

Pressure connections are marked with (+) and (-) symbols on the equipment.

When measuring differential pressure, the higher pressure is connected to the (+) side and the lower pressure is connected to the (-) side. In 2-channel working mode, (+) is connected to channel 1, and (-) is connected to channel 2.

Please note:

When installing and disassembling pressurized pipelines, ensure that the screw socket does not rotate.

If the screw socket rotates, this may cause water leakage. To prevent this from happening, tighten the hexagon of the screw socket with a wrench.

FISCHER pressure transmitter products:

1. FISCHER pressure products (FISCHER pressure instruments)

FISCHER pressure gauge product classification: pressure gauge, electric contact pressure gauge, pressure transmitter

FISCHER pressure gauge display mode: pointer, digital display

FISCHER pressure gauge measurement range: -1~+600bar

FISCHER pressure gauge accuracy: ± 0.25% FS

FISCHER pressure instrument models: MA11, MA12, MA13, ME01, ME02, ME05, ME11

ME1, ME13, ME4, ME50, ME69, etc

2.FISCHER differential pressure products

FISCHER differential pressure product classification: differential pressure gauge, differential pressure switch, differential pressure transmitter, differential pressure gauge

FISCHER differential pressure product display method: pointer, digital display

FISCHER differential pressure product measurement range: -1~+40bar (minimum range 25Pa)

FISCHER pressure difference product accuracy: ± 0.1% FS

FISCHER differential pressure product models: DA01, DA02, DA03, DA08, DE03, DE05, DE13, DE15, DE27, DE43,

DE44, DE45, DE46,

DE49, DS11, DS13, DS21, DS27, DS31, etc

3.FISCHER temperature

FISCHER product classification: thermal resistance, thermocouple, temperature transmitter

FISCHER display method: pointer

FISCHER measurement range: -50~+600 ℃

FISCHER accuracy: ± 0.08% FS

FISCHER models: TS01, TS61, TW10, TW23, TW30, TW40, TW50, TW68, TW70, etc

"ATEX94/9/EC explosion-proof equipment directive"

No file

No file