Service Hotline

0411-87307760

Technical selection sales hotline

Technical selection sales hotlineTel:041187307760

Mobile:18804209403

Q Q:703738287

E-mail:sales@dlleader.cn

About HKS Company

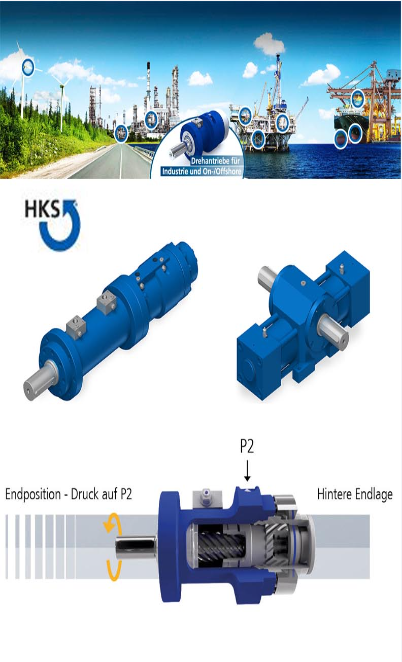

After nearly 50 years of development, German HKS company has now become synonymous with rotary cylinders and swing hydraulic cylinders. It is one of the first companies in the world to develop and mass produce swing hydraulic cylinders. We are still the top company in this professional field to this day.

HKS hydraulic rotary swing cylinder is a tightly assembled hydraulic and pneumatic transmission device developed, designed, and manufactured by enterprises for rotation and swing, capable of acceleration, braking, positioning, and stopping heavy objects. In addition to numerous industrial applications, we also provide customized solutions to manufacturers of construction machinery and mining industries, providing them with internationally recognized, sturdy and efficient rotary swing cylinder connection quick change systems.

Widely used in the following fields:

Demolition engineering technology, excavator accessories, high-altitude work platforms, automotive industry, excavator bucket adjustment, construction machinery, mining machinery, concrete spraying machines, bending machines, container cranes, printers, vehicle design, automotive engineering, meat processing equipment, forestry equipment, foundries, lighting technology, power plants, municipal equipment, crane design (ships), ball valves, agricultural machinery, food industry, logistics, ventilation technology, mechanical design, metallurgy, Hybrid technology (such as dyes), assembly lines, ports, offshore construction, test benches, refineries, industrial robots, shipbuilding, steel industry, machine tools, yacht manufacturing, etc.

1-HKS hydraulic rotary swing cylinder:

1. HKS hydraulic rotary swing cylinder is a tightly assembled hydraulic and pneumatic transmission device developed, designed, and manufactured for rotation and swing, capable of acceleration, braking, positioning, and stopping heavy objects.

2. In addition to numerous industrial application fields, HKS also provides customized solutions to construction machinery and mining industry manufacturers, providing them with internationally recognized, sturdy and efficient rotary swing cylinder connection quick change systems.

3. As a hydraulic actuator for valves, it is used in various ball valves, butterfly valves, etc., with various options available, including buffering, angle adjustment, aluminum casing, stainless steel, retaining valve, rotation angle detection, sealing, ATEX, different installation methods of flanges, different output forms of flat keys, splines, hollow shafts, etc. Various hydraulic actuators can be customized for customers.

4. Multiple reverse helical gear design, the linear motion of the piston is converted into shaft rotation through multiple helical gears, with a compact structure and high torque output. Widely used in industries such as automation, movable hydraulic devices, food, chemical, energy, power plants, municipal, special vehicles, tunnels, construction, engineering machinery, etc.

5. The quick change connection system opens up new application fields for excavators by adding two degrees of freedom of rotation and swing, supporting the quick change system. It can complete operations in limited space, quickly change different accessories, greatly improve human-machine efficiency, increase construction scope, and ensure construction safety.

6. High torque, high load, leak free, maintenance free, suitable for various harsh working conditions. Used in Norwegian AMV drilling rigs, German Putzmeister wet spraying rigs, and other drilling rod swing machines, it is also a standard configuration for domestic customers such as China Railway Construction Three Arm Drilling Trolley and Sany wet spraying manipulator.

2-HKS Siemag Mill Balance Cylinder

HKS is applied to the balance vertical roller of the Siemag universal rolling mill, and the balance cylinder DHK-H-ZV 90 90 of the HKS Siemag rolling mill

HKS Sigma Mill Balance Cylinder DHK-H-ZV 90 90 Product Features:

The maximum working pressure is 210bar, the maximum torque is 14700Nm, the rotation angle can reach 360 °, the maximum lifting stroke is 1200mm, the lifting force is 360000Nm, and the traction force is 180000Nm.

HKS is applied to the flat steel strip of the Ximak hot rolling mill, and the flat cylinder DEK-H 120 198 of the HKS Ximak rolling mill, etc

HKS Sigma Mill Flattening Cylinder DEK-H 120 198 Product Features:

The maximum working pressure is 210bar, the maximum torque is 40000Nm, and the rotation angle can reach 720 °. It has a foot mounted gear rack structure.

3-HKS excavator quick change system

HKS excavator quick change system XTRATILT, HKS excavator quick change system ROTOBOX, HKS12 ton excavator quick change system TR-120, etc.

The TR-120 quick change system of the HKS12 ton excavator expands the working range of the excavator by adding two degrees of freedom (swing and rotation), which is equivalent to installing a wrist on the excavator. The upper and lower working devices are connected to each other through an automatic quick change connection system. Equipped with various accessories, it is equivalent to a construction team composed of one excavator, which includes demolition, loosening, crushing, loading and unloading, trenching, logging, milling, vibration, rotary excavation, etc.

HKS12 ton excavator quick change system TR-120 product features:

HKS Excavator Quick Change System XTRATILT

54 models, 18 sizes, up to 100t, swing angles of 100 °, 140 °, 180 °, holding torque of 165000Nm.

By rotating the joint, 5 sets of oil circuits are produced, with a flow rate of 500L/min. They can be installed separately or through flanges or welded up and down quick change connections.

HKS Excavator Quick Change System ROTOBOX

7 sizes are available, suitable for 1t to 55t excavators, with a torque of 12000 Nm and a rotational speed of 8 revolutions per minute. It can be installed separately or with flanges or welded up and down quick change connections.

HKS12 ton excavator quick change system TR-120

10 standard sizes, ranging from 2t to 55t, can achieve an axial load of 40000 Nm and a radial compliance of 25000 Nm. The torque can be maintained at 52000 Nm, and can be individually or flange mounted or welded for quick change connections.

4-HKS multi spindle machine tool rotary table swing cylinder

HKS applies multi spindle machining centers for automotive components, rotary table swing cylinders, and HKS multi spindle machine tools, such as rotary table swing cylinder DA-H 100 182 °.

HKS multi spindle machine tool rotary table swing cylinder DA-H 100 182 ° Product features:

The maximum working pressure is 210bar, the maximum torque is 250000 Nm, the rotation angle can reach 360 °, and the special angle can reach 1500 °. It has a large torque output, a compact structure, and is maintenance free.

No file

No file