Service Hotline

0411-87307760

30-WTE

Angled thermocouple assemblies with threaded elbow tubing

Angled thermocouple assemblies with threaded elbow tubing (30-WTE) are primarily used for temperature measurement in metal smelting and salt baths.

The Angled shape allows for placement of the connection head away from the actual bath/smelt in order to avoid direct exposure to high temperatures and aggressive vapours.

Angled thermocouple assemblies with threaded elbow tubing offer the advantages of an exchangeable immersion tube and the pos- sibility of using more economic material for the supporting tube due to reduced ambient stress factors.

GÜNTHER GmbH has all prevalent angled thermocouples used in smelting and foundry technology. Standard assemblies with immersion tubes made of steel, pure iron, heat-resistant steels and special alloys are applied, as well as silicon nitride, graphite, SIC or special metal ceramics.

Optionally, these thermocouple assemblies may be fitted with in an internal ceramic tube, which significantly increases the long-term stability and electrical insulation in many application scenarios. As an alternative to the installed thermocouple, numerous angled thermocouple assemblies may be fitted with a mineral-insulated measuring insert, which yields several crucial advantages, such as optimal protection of the inner conductors from corrosion, oxida- tion, physical damage, and chemical contamination due to the enclosed structure of the outer insulation.

In order to ensure functionality of the thermocouple assembly during a suitable timeframe, careful consideration should be used when selecting the materials for thermocouple and Protection tube depending on the operating conditions.

Thermoelectric voltages and tolerances of our thermocouples and mineral-insulated measuring inserts are according to DIN EN 60584, class 1, for thermocouples and mineral-insulated measuring inserts of type L according to DIN 43710.

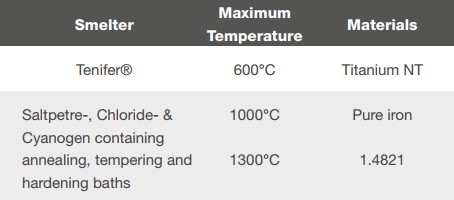

Recommended protection tube materials in salt baths

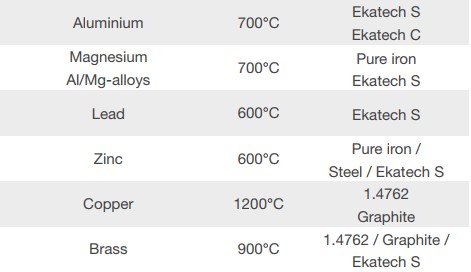

Recommended protection tube materials in metal smelting: